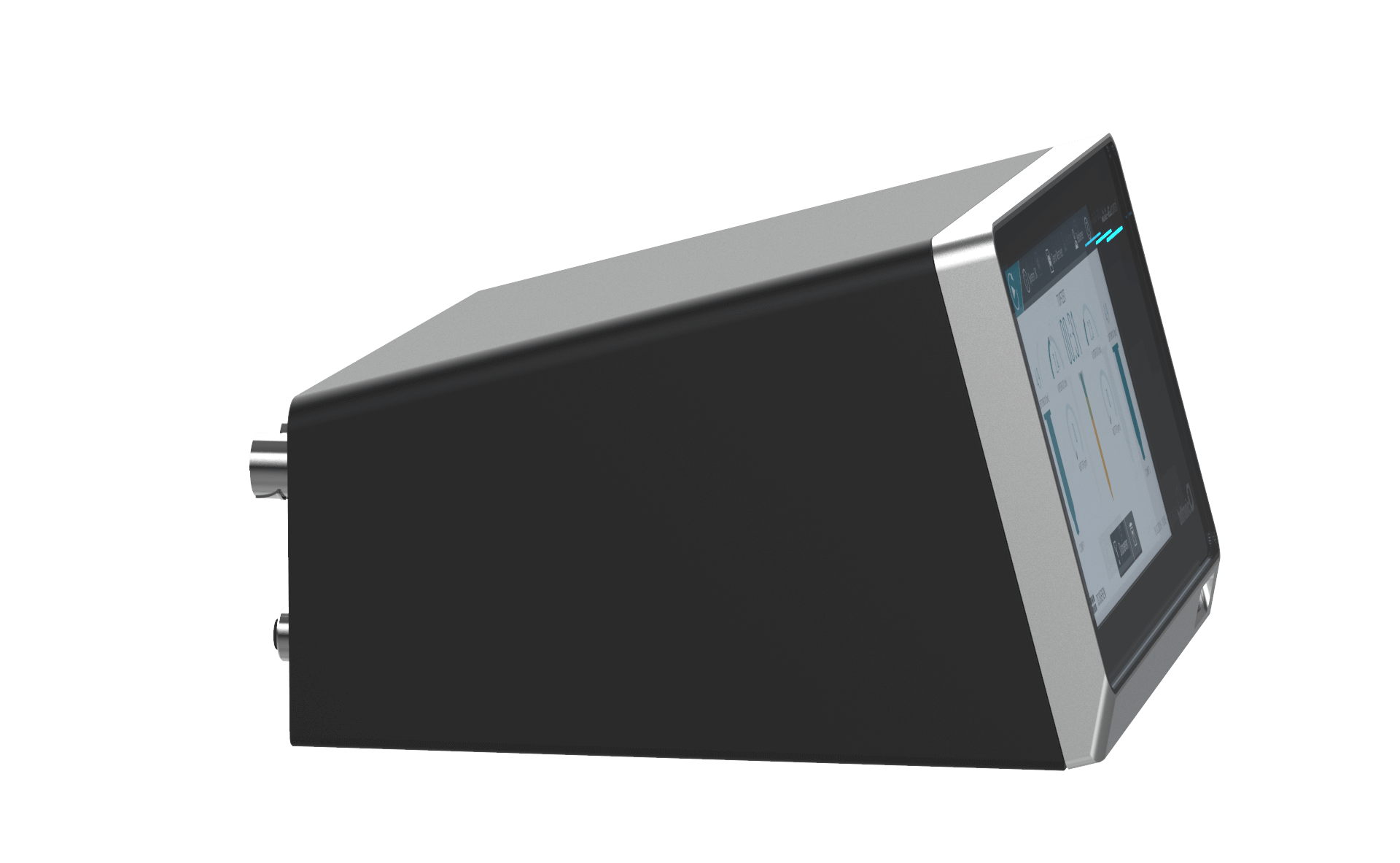

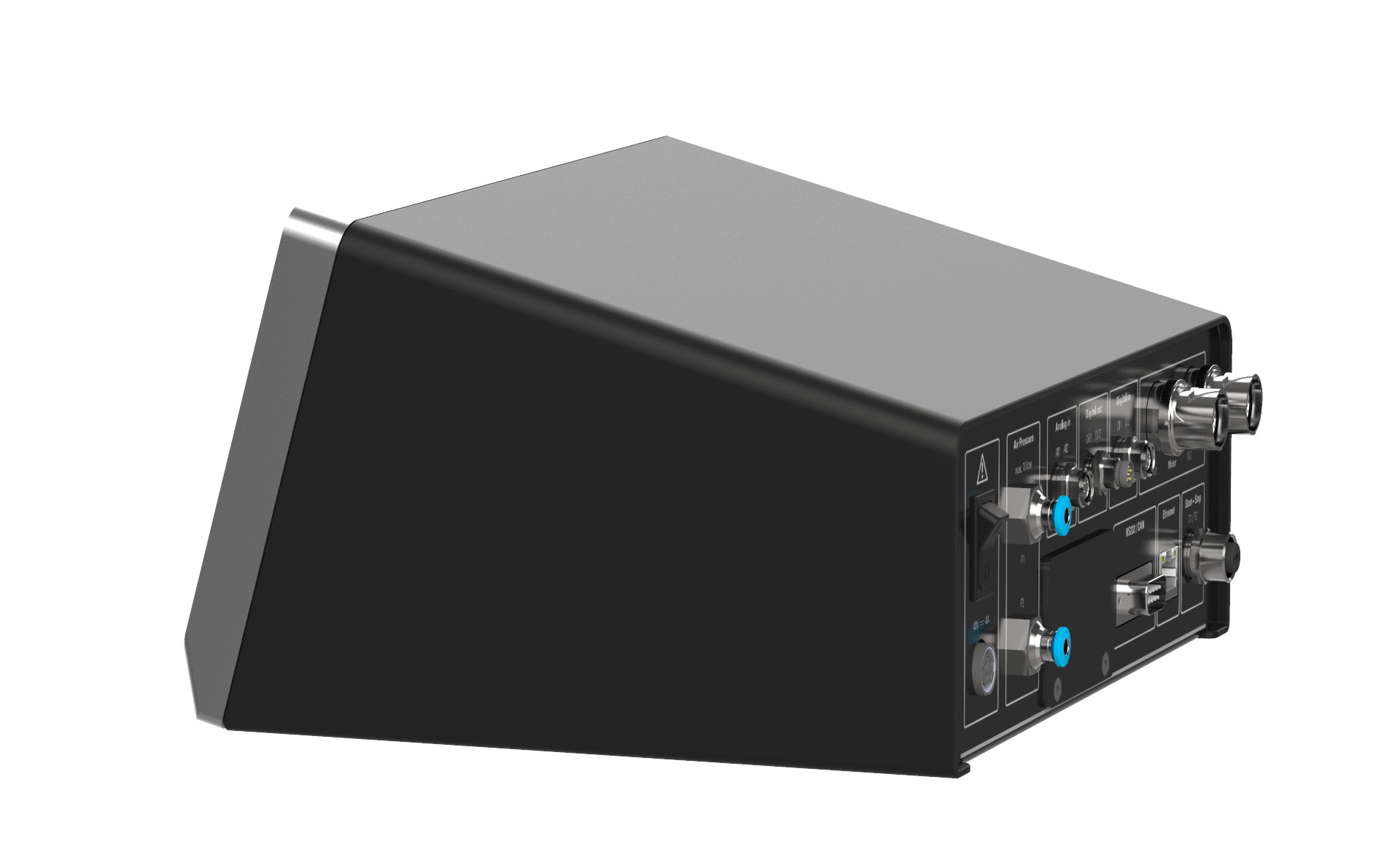

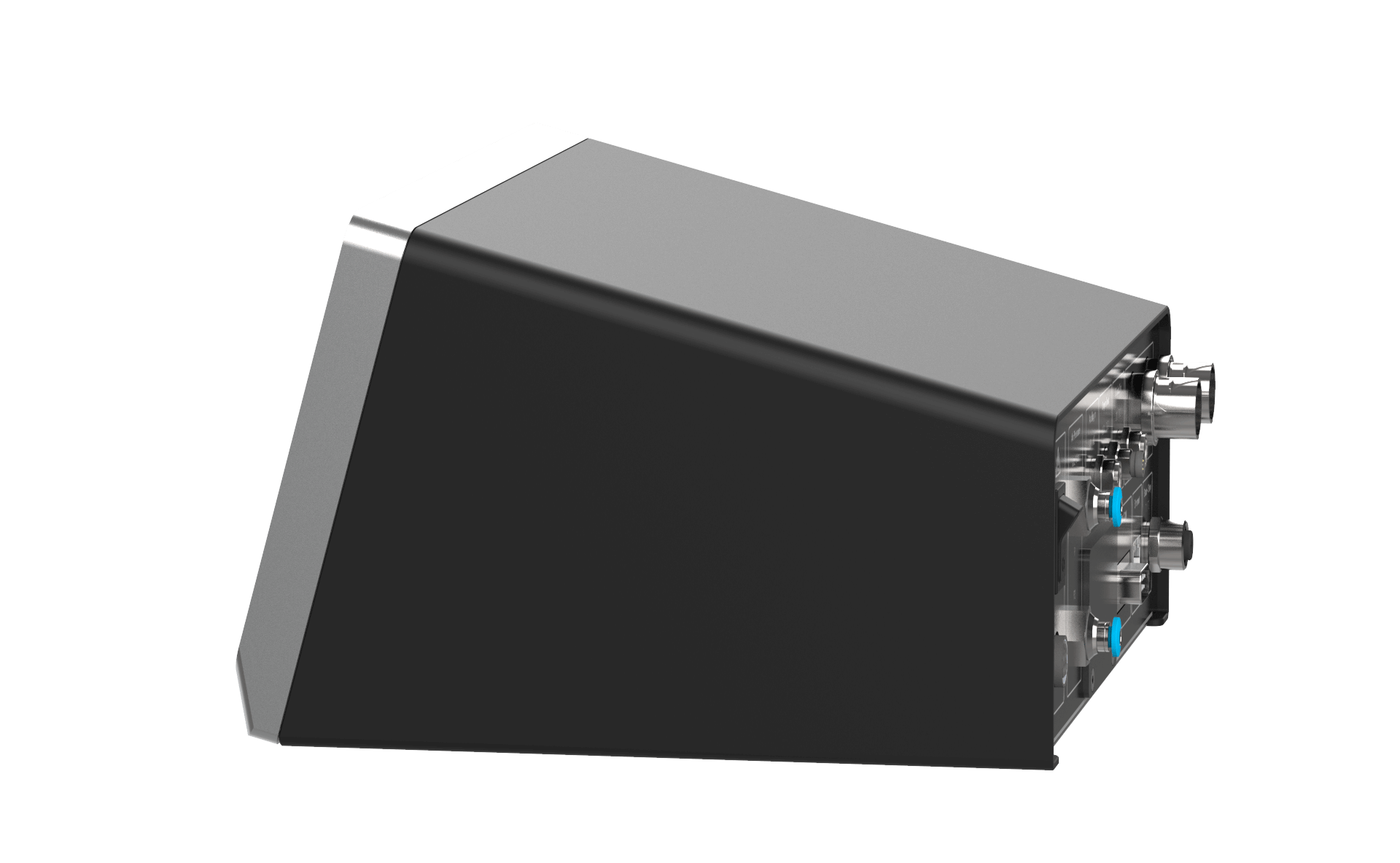

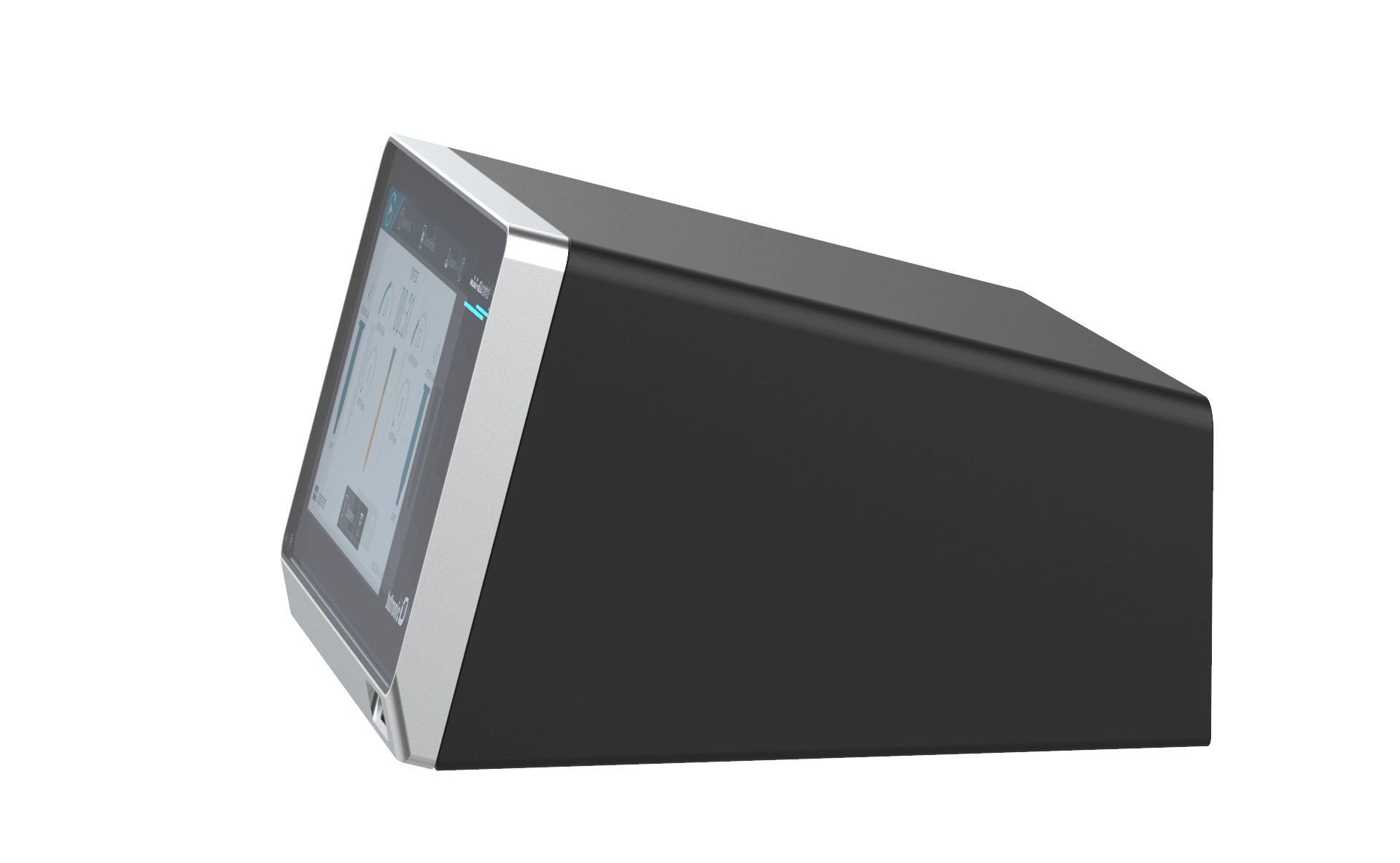

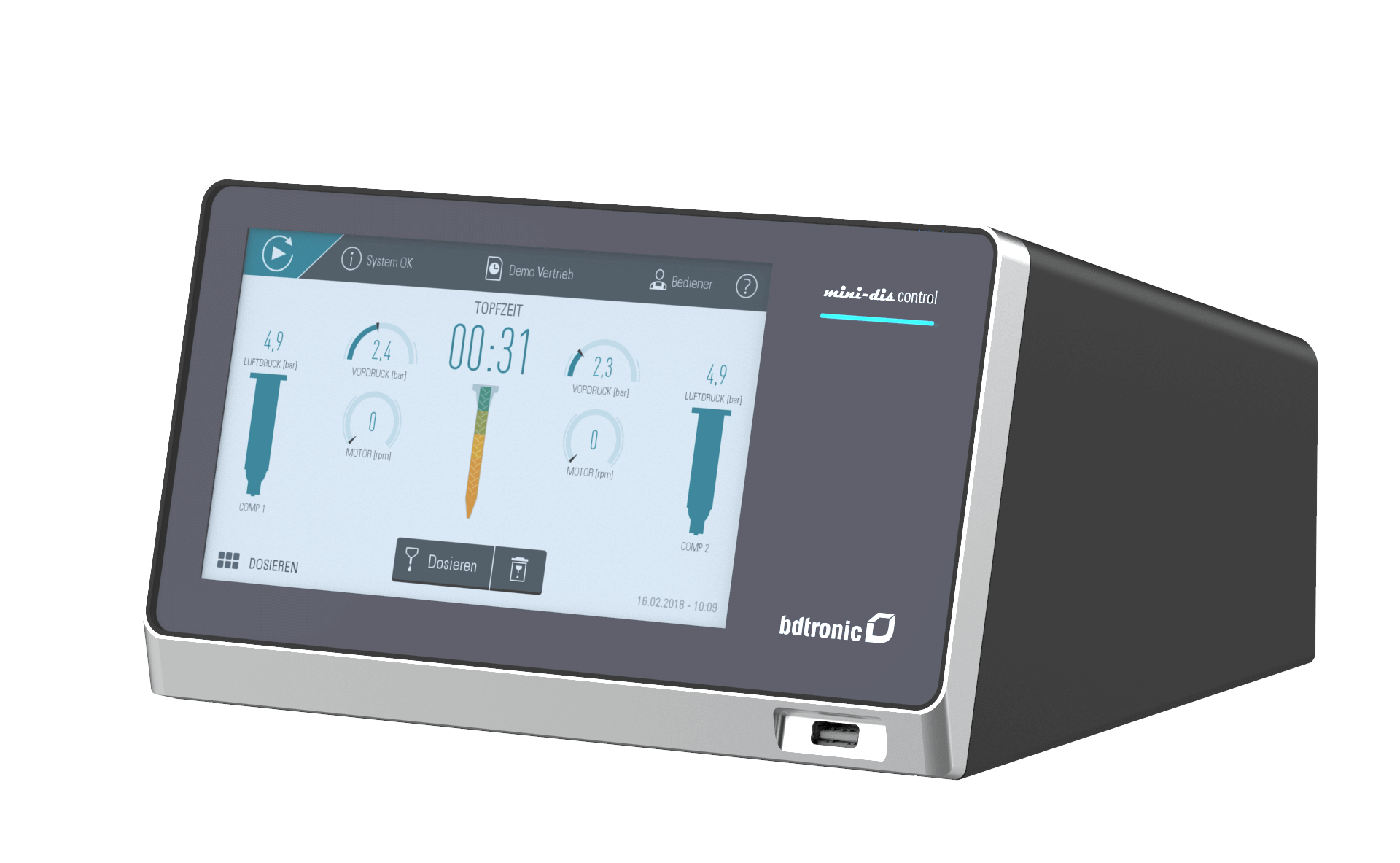

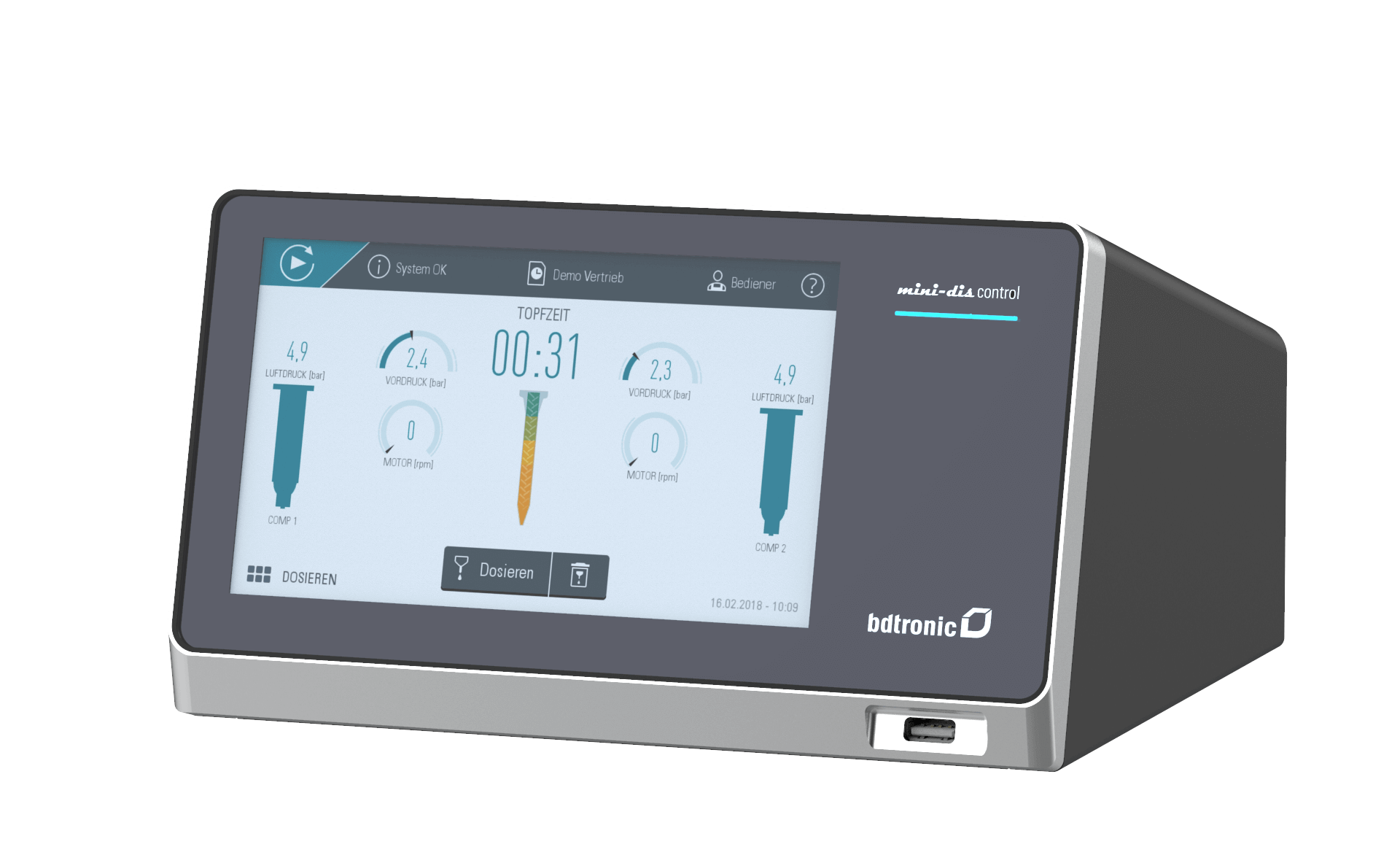

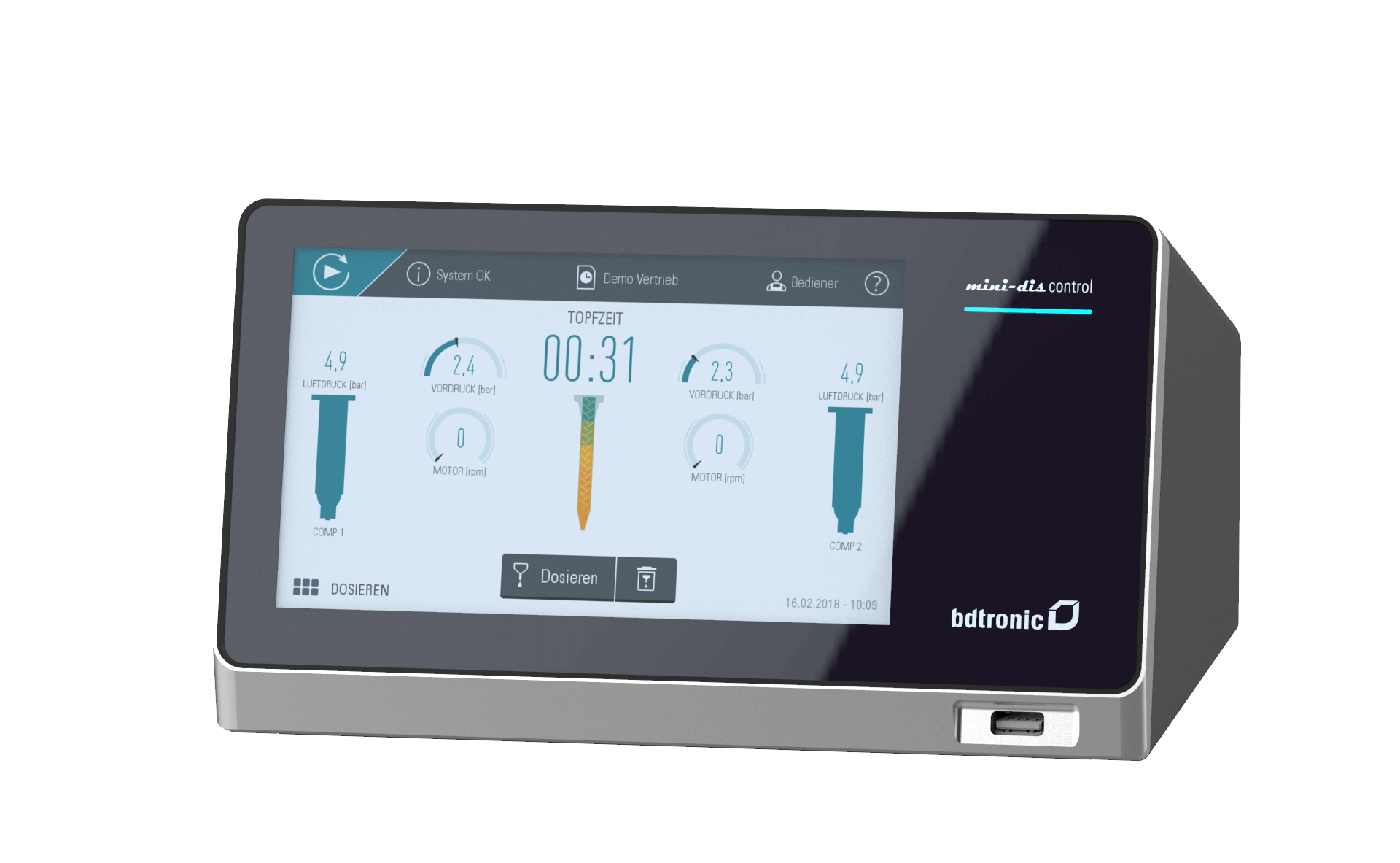

Micro dispensing control unit

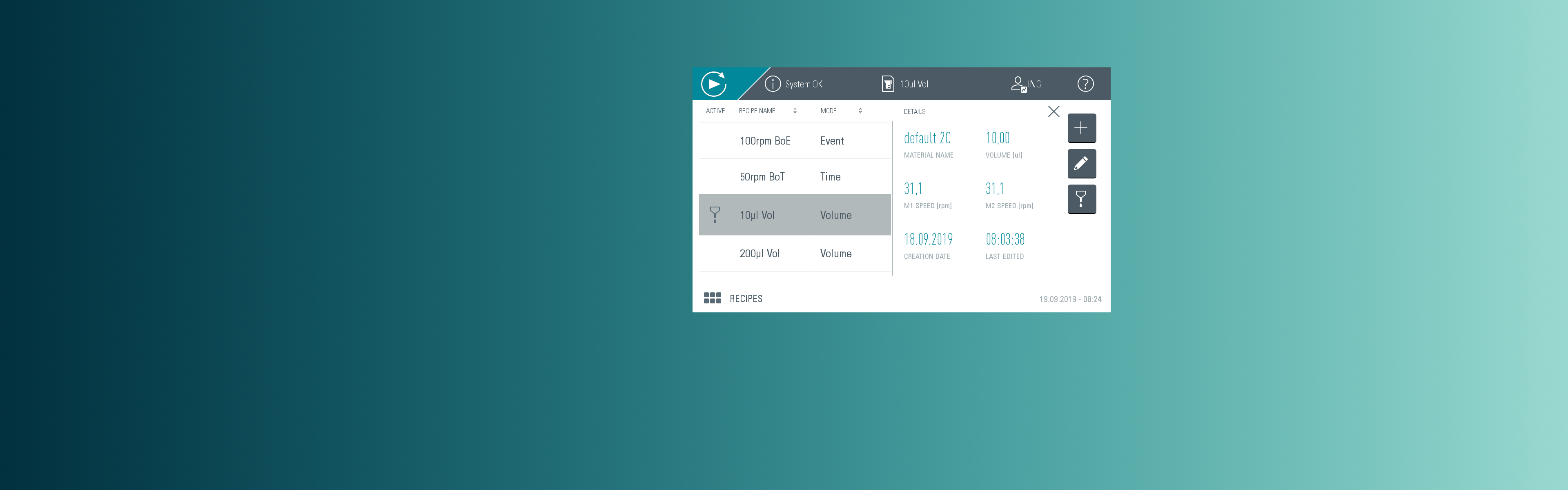

The material database can save up to 1,000 different materials. After selecting a suitable recipe, the process parameters are set automatically. As a result, incorrect settings can be excluded.

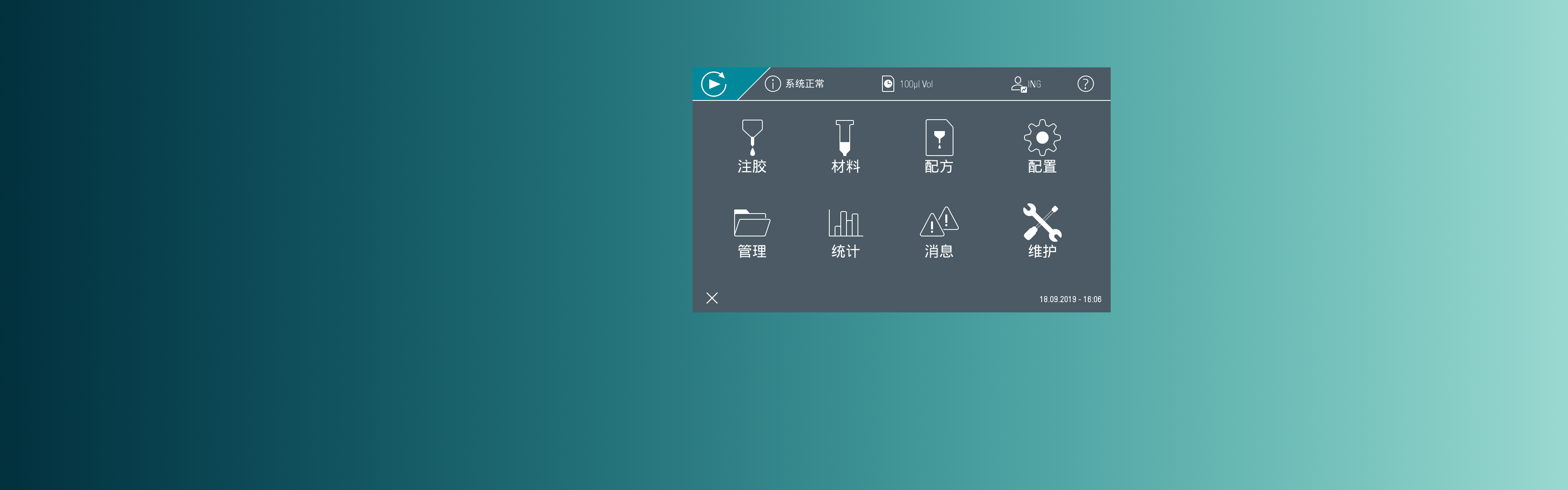

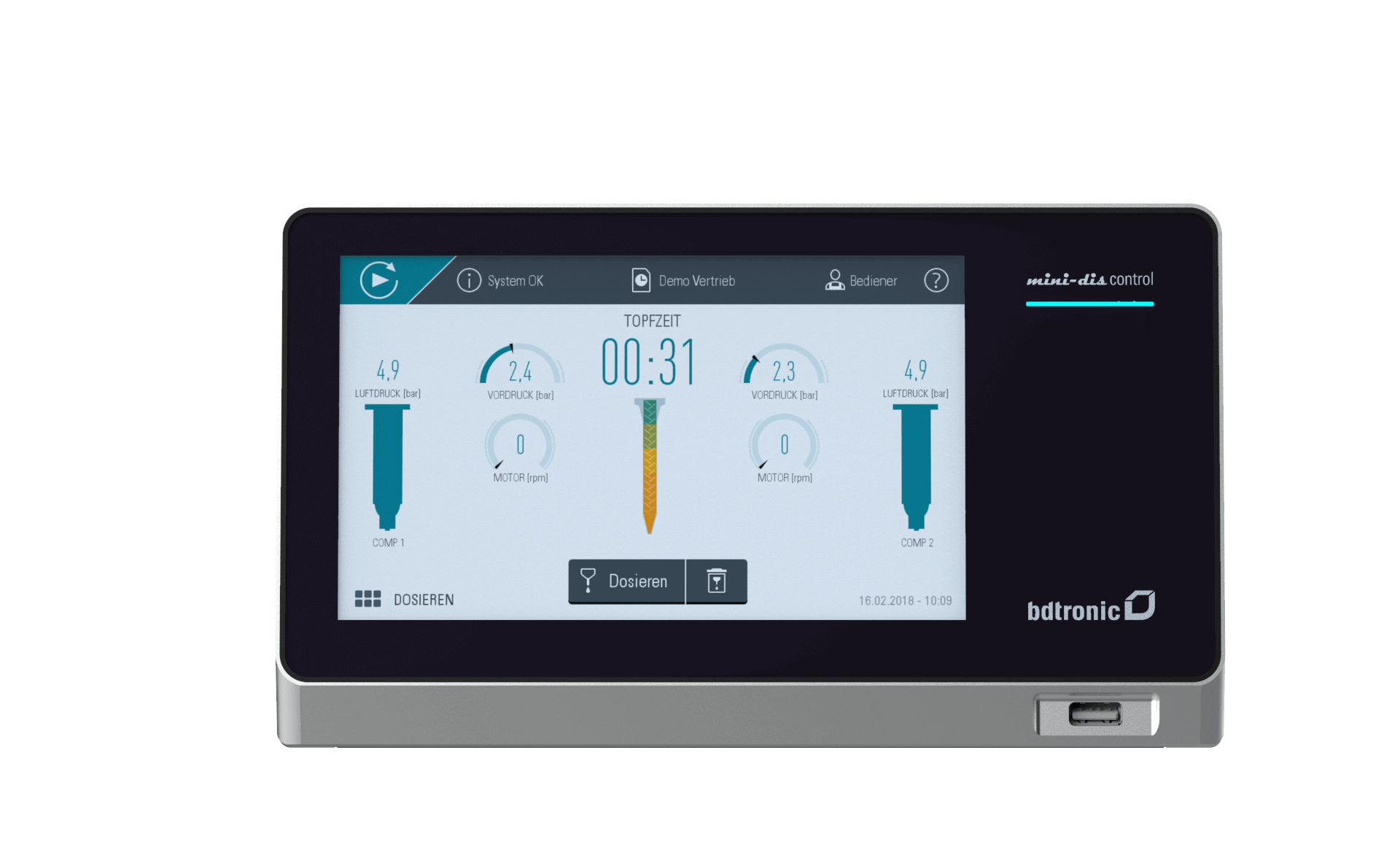

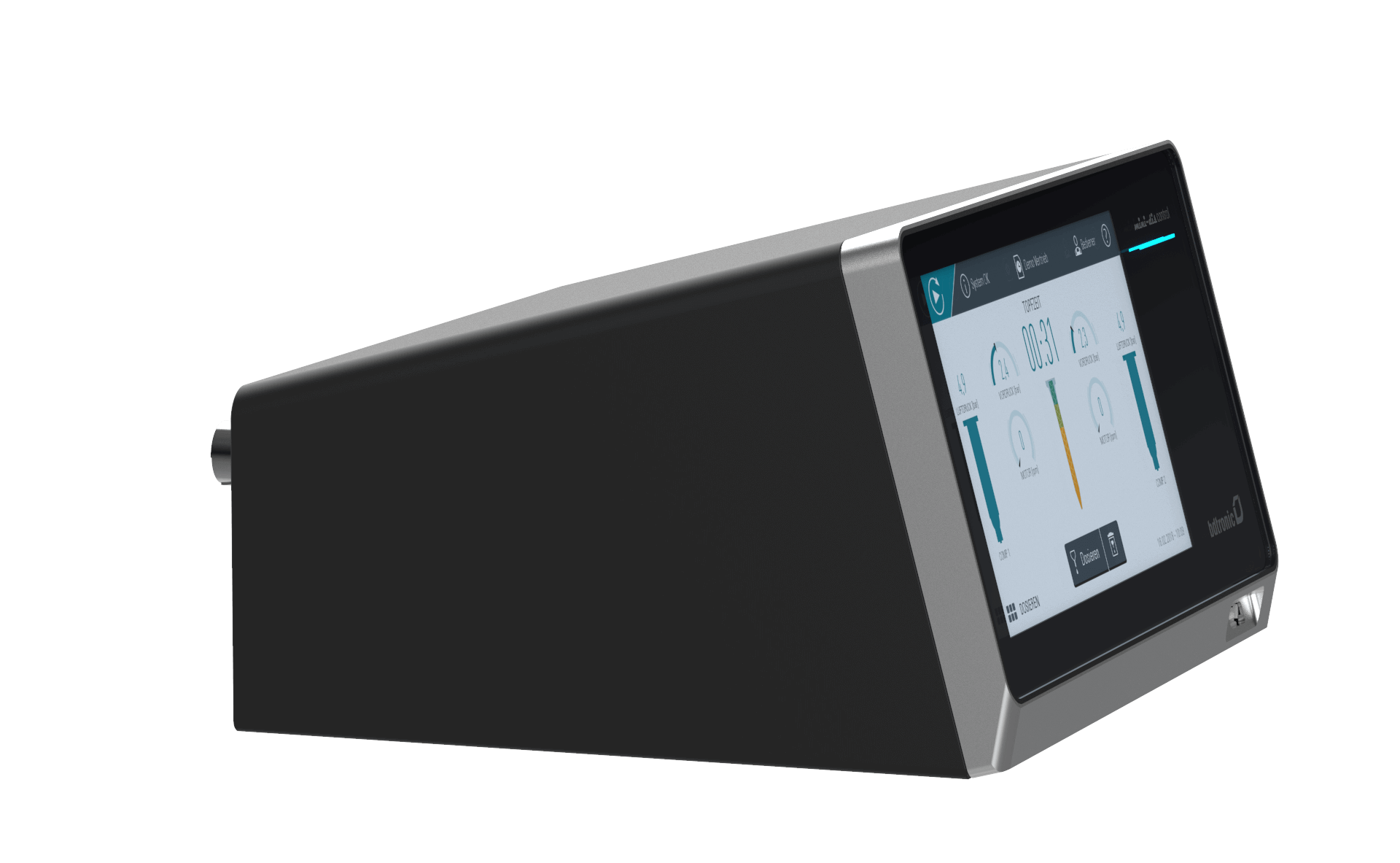

The mini-dis control ensures easy operability via the innovative HMI. It offers independent presentations mini-dis 1K and 2K, as well as for the entire sensor system.

More Videos

The mini-dis control also offers complete monitoring of all relevant parameters, due to the specially developed software by bdtronic, as well as optimum servomotor control. In addition to process-reliable and precise metering in the microliter range, the control unit also enables the highest precision and accuracy.

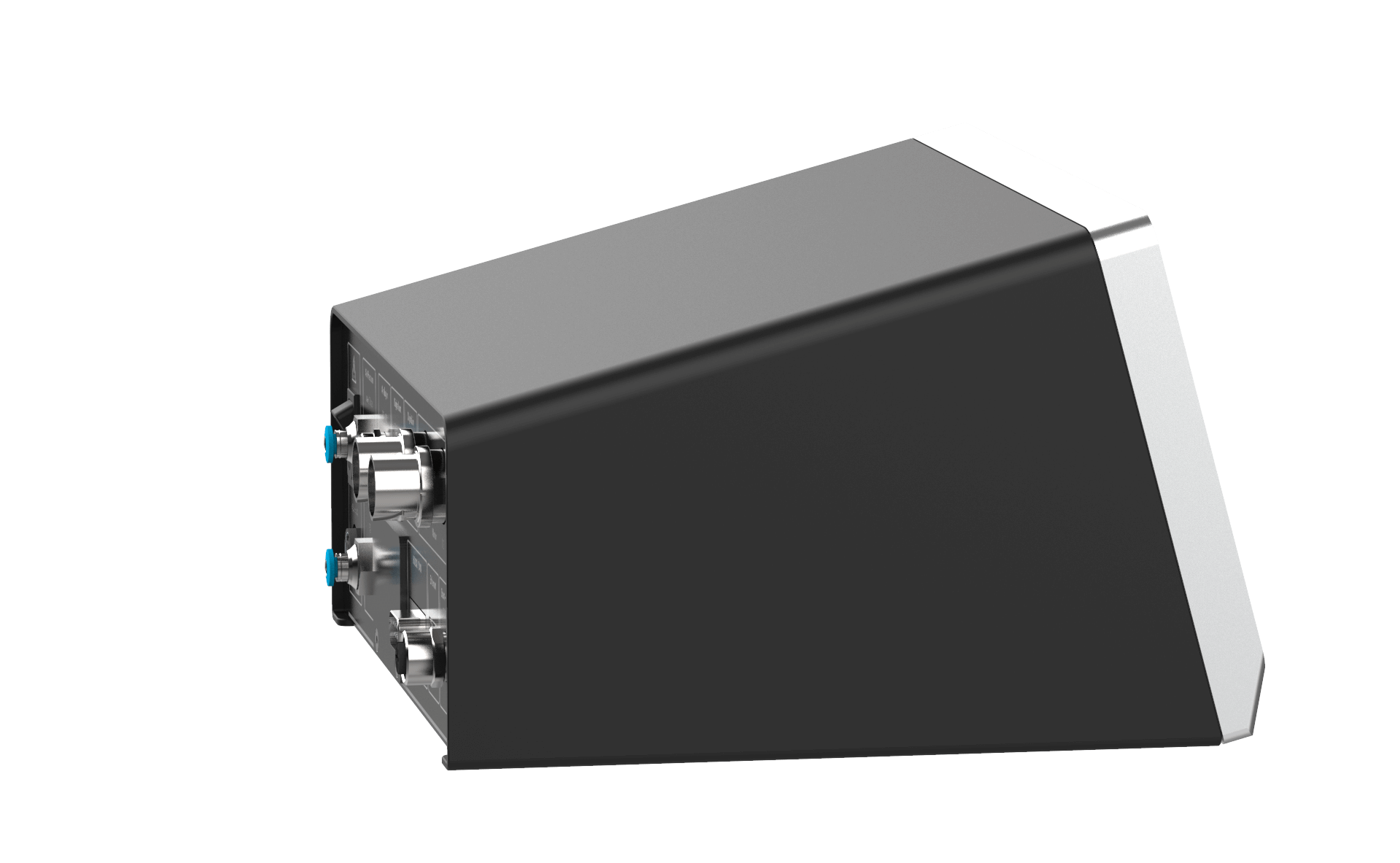

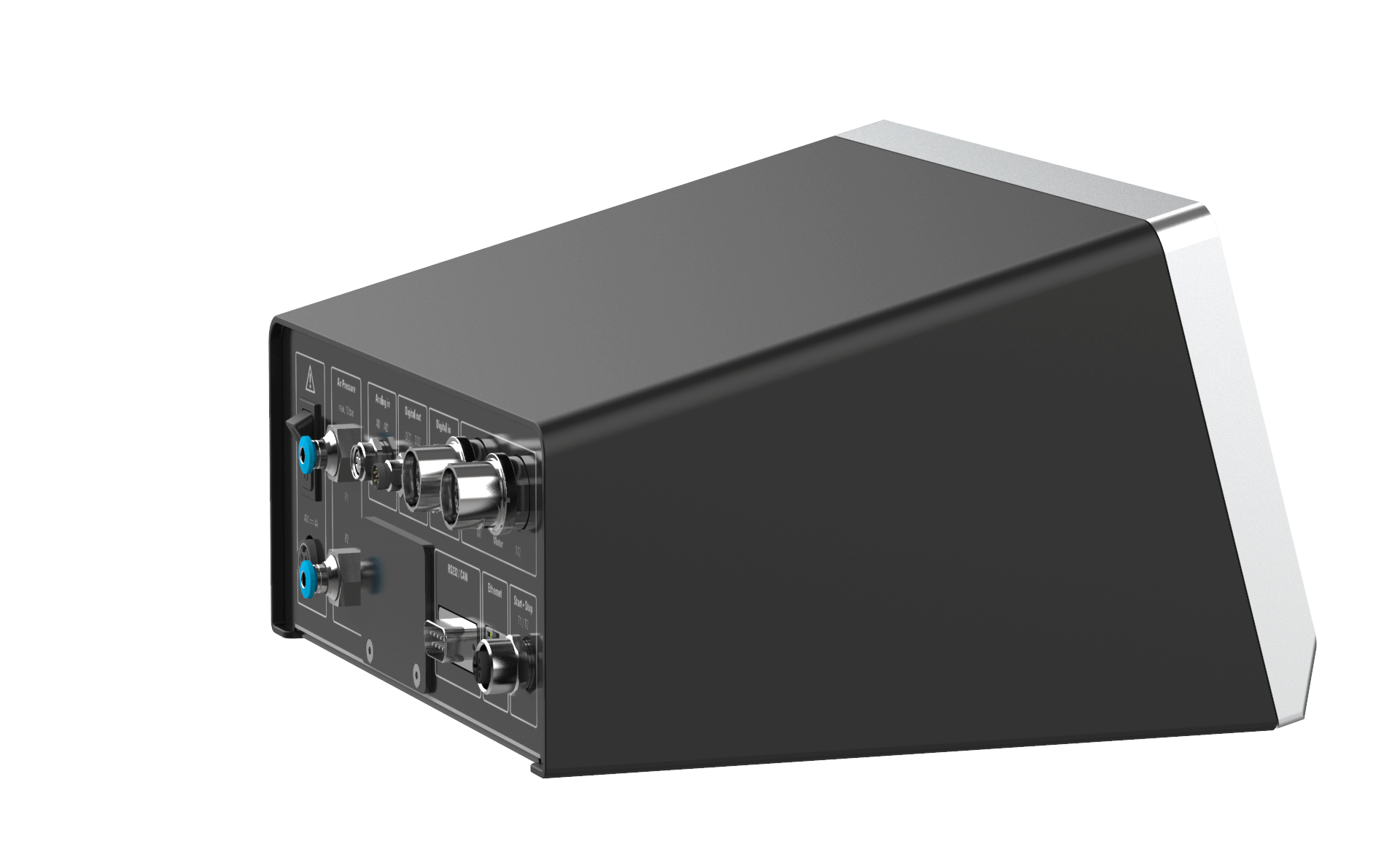

Connections

• Analog In for pressure and level sensor

• Digital In/Out for machine communication

• Connections for servomotors for pumps

• Foot switch or machine communication interface

• Ethernet port for local network connection

• Connection extensions via CAN-Bus / RS232

• Insertion slot for interface modules (optional)

Technical Data

| Dimensions (W x H x D): | 230 x 200 x 140 mm |

| Weight: | 1,9 kg |

| Power Supply: | 110 / 230 V; 50 / 60 Hz |

| Power consumption: | 200 W |

| Protection class: | IP 20 |

| CB-scheme: | IEC 61010-1:2010 |